Nā ʻāpana a me nā mea hoʻohana

Hāʻawi mākou i nā ʻano mea hana like ʻole, shafts, motors, pahu hoʻouna, ʻāpana uila, nā ʻano like ʻole o nā ʻāpana ʻokoʻa i loaʻa, a me nā ʻāpana ʻokoʻa i hana ʻia; e ʻoluʻolu e haʻi mai iā mākou i ke kumu hoʻohālike a i ʻole nā kiʻi huahana. Hāʻawi mākou i nā lako a me nā lawelawe kūpono loa.

Na Lako Paipu Mill

| Paʻa ferrite mākēneki | Paipu aniani |

| Ma waho o ka ʻoki ʻoki a me ka ʻāpana pahi | ʻike maka |

| ʻO loko o ka ʻōpala a me ka ʻāpana pahi | Coil induction |

| Pūnaehana hoʻoheheʻe Zinc | |

Pono ka hoʻomaʻemaʻe a me ka mālama ʻana i nā lako, a pono e hoʻololi ʻia nā mea pono i ka manawa.

No ka meaERW Tube MillKa mālama ʻana a me ka hana ʻana o ka mīkini:

a. Hoʻokahi manawa i ka pule e nānā i ka emulsion a me ka hale hoʻomaha no ka hana ʻana i ka wai a me ka ʻaila.

b.E hoʻolohe i ka lubrication hoʻohui o nā bearings, pahu pahu hoʻemi wikiwiki a me ka rack. Inā emi ka lubrication ma ka pahu ho'ēmi wikiwiki ma mua o 5000Hr, a laila pono e hoʻololi; hoʻohui ʻia ka ʻaila i hoʻokahi manawa i ka pule.

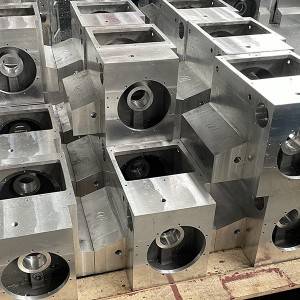

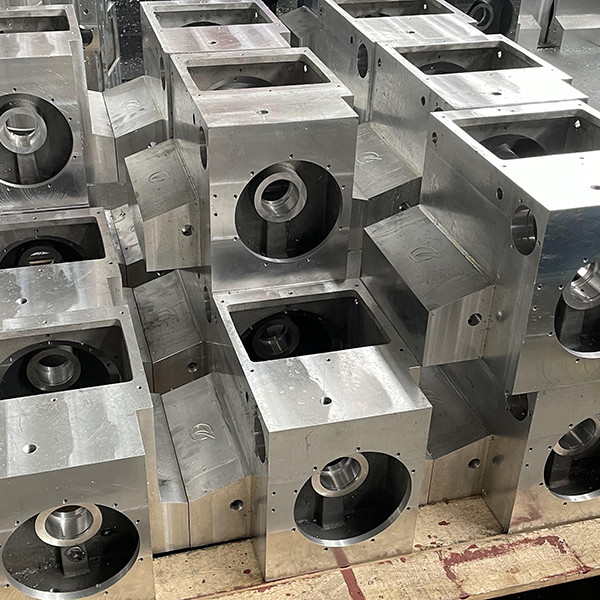

SS Pipe Mill Mold

Hoʻohana kā mākou mold i ka ʻōnaehana CNC, ke kaʻina hana kiʻekiʻe ʻO ka hoʻohana ʻana i ka Cr12mov, SKD11, D2, ma hope o ka hoʻomaʻamaʻa wela kūikawā, paʻakikī a hiki i 61-63HRC No ka hana ʻana o ka paipu puni, Roundness i loko o 0.05mm; No ka hana ʻana i ka paipu huinahā, ka ʻaoʻao palahalaha ʻoi ʻoi, ma hope o ka polishing, hiki ke aniani ka ʻili.

No ka meaStainmīkini hana paipu hao liʻiliʻiKa mālama ʻana a me ka hana ʻana o ka mīkini:

a. E ʻoluʻolu, mai kau i nā mea hana, nā wili, a me nā mea ʻē aʻe ma luna o nā mea uila, e like me nā pamu, e pale i ka haʻalulu uila.

b. Hoʻopaʻa loa ʻia ke komo ʻana i nā mea hana no ka hoʻonohonoho ʻana a me ka mālama ʻana, a i ʻole e kau i kou lima ma waena o nā wili kū pololei a i ʻole e huki i ka mea i ka wā e holo ana nā mea hana.

c. Ma hope o ka hoʻohuli ʻana i nā mea hana, e nānā pono inā e hana maʻamau ka kaʻa, ka mea hoʻoemi, ka pahu pahu, nā wili a me ke ākea me ka leo ʻole a me ka haʻalulu.

d. Pono e loaʻa i kahi kūpono a me nā kukui a puni ka ʻōnaehana no ka hana palekana a me ka mālama ʻana.

e. I ka hana ʻana i ka hoʻoheheʻe welding, e hoʻokomo ka mea hoʻohana i nā mīkina lima wela a me nā maka aniani.

f. E mālama pono i nā mea hana.

g. Hāʻawi i ka ea kūpono inā pono.

h. E hōʻoia i nā ala māmā a me nā kukui kūpono.